Introduction: Revolutionizing Aerospace with Advanced Materials

Carbon Fiber Reinforced Plastics (CFRP) have rapidly emerged as a critical material in aerospace engineering, offering a compelling combination of strength, lightness, and corrosion resistance. As the aviation and space exploration industries continue to seek innovative solutions to enhance performance, reduce emissions, and optimize fuel efficiency, CFRP stands out as a transformative material. It is now used extensively in aircraft structural components, interiors, and propulsion systems. From commercial jets to military aircraft and satellites, CFRP is shaping the next generation of aerospace technology, driven by a growing need for lighter and more resilient materials.

Market Outlook: Robust Growth Trajectory Ahead

The global carbon fiber reinforced plastics market is on a strong upward trajectory, largely fueled by rising demand across aerospace applications. According to the Persistence Market Research report, the global carbon fiber reinforced plastics market size is expected to increase from US$ 30.2 billion in 2025 to US$ 54.5 billion by 2032. This impressive growth represents a compound annual growth rate (CAGR) of 8.8% during the forecast period. The surge is attributed to both the rising adoption of CFRP in high-performance aircraft components and increasing investments in lightweight materials by aerospace manufacturers to meet sustainability and efficiency goals.

Why is Carbon Fiber Important in Aerospace?

CFRP’s importance in aerospace lies in its unique properties—exceptional strength-to-weight ratio, high fatigue resistance, thermal stability, and excellent corrosion resistance. These qualities make it ideal for manufacturing critical parts like fuselages, wings, tail sections, and rotor blades. Its ability to reduce aircraft weight directly translates into lower fuel consumption, reduced emissions, and extended range. Additionally, CFRP materials help in reducing maintenance costs due to their longer lifecycle compared to traditional metals such as aluminum or steel. These advantages make CFRP an irreplaceable material for next-gen aerospace design.

What are the top uses of CFRP in aerospace applications?

“What are the main applications of carbon fiber reinforced plastics (CFRP) in the aerospace industry?”

CFRP plays a vital role across multiple aerospace applications, ranging from structural components to cabin interiors. In commercial aircraft, CFRP is used in wings, fuselage skins, landing gears, floor beams, and engine nacelles, significantly contributing to weight reduction and fuel efficiency. In military aviation, the material supports stealth capabilities and high-performance demands, particularly in fighter jets and unmanned aerial vehicles (UAVs). Spacecraft and satellites utilize CFRP for antenna reflectors and payload structures due to its thermal stability and low mass. Overall, CFRP’s diverse applications enhance flight performance, safety, and sustainability across all aerospace platforms.

Key Applications in Aircraft Structures

A major area where CFRP is making a substantial impact is in the primary structures of aircraft. Airbus and Boeing, two of the world’s largest aerospace manufacturers, have adopted CFRP extensively in their aircraft designs. The Boeing 787 Dreamliner, for instance, consists of nearly 50% CFRP by weight. These composites are used in the fuselage, wings, tail, and doors. The weight savings achieved through CFRP integration allow for more passengers, improved fuel economy, and extended range—factors that are increasingly important in today’s competitive aviation market. Additionally, CFRP’s resistance to fatigue and corrosion improves aircraft longevity and reduces the total cost of ownership.

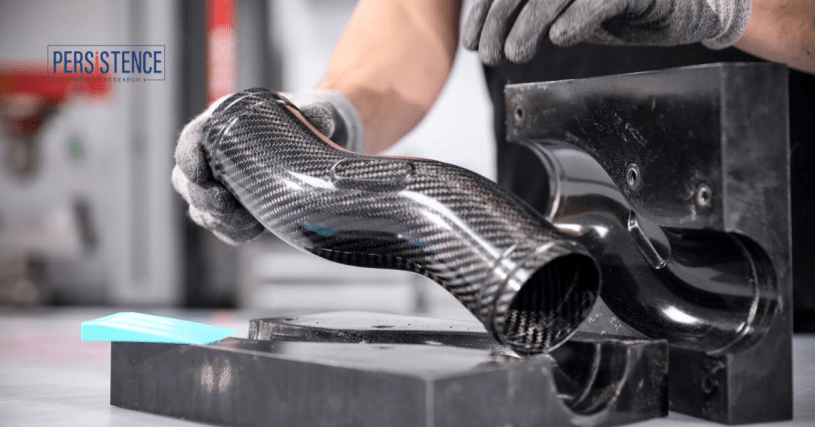

Propulsion Systems and Engine Components

CFRP is also revolutionizing aerospace propulsion systems. Jet engines and turbofan components increasingly incorporate CFRP due to its ability to withstand extreme temperatures and high stress levels. Components such as fan blades, compressor cases, and nacelle structures benefit from CFRP’s strength and light weight, which help optimize thrust-to-weight ratios and minimize fuel consumption. The integration of CFRP in engine design not only improves performance but also helps achieve stringent emission targets set by international aviation authorities.

CFRP in Spacecraft and Satellites

Space exploration demands materials that are both lightweight and capable of withstanding harsh environmental conditions, including extreme temperatures and radiation exposure. CFRP is widely used in satellite bus structures, deployable booms, and antenna reflectors. It ensures dimensional stability and durability without adding excessive weight—a critical requirement for successful launches and operations in orbit. As more countries and private firms enter the space race, demand for advanced CFRP components in spacecraft is expected to rise, contributing to the overall growth of the CFRP market.

Interiors and Cabin Components

Another important area of CFRP application is within the aircraft cabin. Airlines are increasingly using CFRP in seats, overhead compartments, flooring, and side panels to reduce cabin weight and increase payload capacity. These lightweight interior components help airlines save significantly on fuel while enhancing passenger comfort and safety. Additionally, CFRP’s aesthetic appeal and customization potential allow airlines to design modern, efficient, and luxurious cabin environments.

Military Aviation and UAVs

CFRP is playing a transformative role in modern military aviation. Fighter jets such as the F-35 Lightning II make extensive use of CFRP to improve maneuverability and reduce radar detection. UAVs (Unmanned Aerial Vehicles), used for surveillance and reconnaissance missions, benefit from CFRP’s low weight and high durability, enabling longer flight times and better energy efficiency. The combination of stealth, speed, and operational efficiency makes CFRP an indispensable material in the defense aerospace sector.

Benefits Over Traditional Materials

Compared to metals like aluminum or titanium, CFRP offers several advantages in aerospace. It is up to five times stronger and two-thirds lighter than steel and significantly more corrosion-resistant than aluminum. CFRP also allows for greater design flexibility, enabling the creation of complex aerodynamic shapes that were previously impossible with metals. This not only enhances aircraft efficiency but also reduces part count, contributing to easier assembly and maintenance.

Challenges and Considerations

Despite its many benefits, the widespread adoption of CFRP in aerospace is not without challenges. High material and production costs remain a key barrier, particularly for smaller manufacturers. Repair and inspection of CFRP components require specialized techniques and equipment, which can increase maintenance complexity. Moreover, recycling CFRP remains a technical challenge, raising concerns about its environmental impact. However, advancements in manufacturing processes and recycling technologies are gradually addressing these limitations, making CFRP more accessible and sustainable over time.

Future Outlook and Opportunities

The future of CFRP in aerospace looks highly promising. Innovations such as automated fiber placement (AFP), thermoplastic CFRP, and out-of-autoclave (OoA) processing are expected to reduce costs and improve production efficiency. As the aviation industry moves toward net-zero emissions and electric flight, CFRP will play an even greater role in developing lightweight airframes and propulsion systems. Additionally, the growing trend of space tourism and commercial space launches opens up new market opportunities for CFRP applications in spacecraft design.

Conclusion: Paving the Way for Next-Gen Aerospace

Carbon Fiber Reinforced Plastics are redefining the aerospace industry by delivering unmatched strength, lightness, and durability. From commercial airliners to cutting-edge military jets and satellites, CFRP is integral to building faster, greener, and more efficient flying machines. With the global CFRP market projected to grow from US$ 30.2 billion in 2025 to US$ 54.5 billion by 2032 at a CAGR of 8.8%, the material’s role in aerospace innovation is only set to expand. As technology advances and cost barriers decline, CFRP will undoubtedly remain at the forefront of aerospace materials engineering, driving performance, sustainability, and design excellence across the skies.

Explore the Latest Trending “Exclusive Article” @