Introduction: Enhancing Durability Across Industries

Scratch resistant coatings have become an essential solution for improving the durability, appearance, and lifespan of surfaces across a wide range of industries. From automotive exteriors and consumer electronics to architectural glass and industrial equipment, these coatings play a crucial role in protecting materials from abrasion, wear, and daily damage. As end users increasingly demand products that retain aesthetics and functionality over longer periods, the scratch resistant coating market is gaining steady momentum globally, supported by technological advancements and expanding application areas.

Market Overview: Size, Growth, and Revenue Potential

The global scratch resistant coating market is witnessing consistent growth as industries focus on performance enhancement and cost-efficient maintenance solutions. According to a Persistence Market Research report, the global scratch resistant coating market is expected to be valued at around US$ 6.4 billion in 2026. Over the forecast period, the market is projected to expand further, reaching approximately US$ 9.3 billion by 2033. This growth reflects a compound annual growth rate (CAGR) of 5.5% during the 2026–2033 period, highlighting stable demand across both mature and emerging markets. The upward trajectory is supported by rising adoption in automotive, electronics, and construction sectors, where surface protection is a critical requirement.

What Is Driving the Growth of the Scratch Resistant Coating Market?

The growth of the scratch resistant coating market is primarily driven by rising demand for durable and long-lasting surfaces across multiple industries. In the automotive sector, manufacturers are increasingly using these coatings to protect vehicle interiors, exteriors, and display panels from wear and tear. In consumer electronics, scratch resistant coatings enhance the lifespan and visual appeal of smartphones, tablets, and wearable devices. Additionally, growth in construction activities has increased demand for coated glass, flooring, and panels. Technological advancements, such as nanocoatings and UV-cured formulations, further improve performance, making scratch resistant coatings a preferred solution for manufacturers aiming to deliver high-quality, premium products.

Get Your FREE Sample Report Instantly – Click Now

Key Growth Drivers: Factors Fueling Market Expansion

One of the major drivers of the scratch resistant coating market is the rapid growth of the automotive and transportation industry. Automakers are under constant pressure to improve vehicle aesthetics, durability, and resale value. Scratch resistant coatings are widely applied to automotive clear coats, plastic components, dashboards, and touchscreens to reduce visible damage and maintenance costs. This trend is particularly strong in premium and electric vehicles, where design and surface quality play a key role in consumer purchasing decisions.

Another significant growth driver is the booming consumer electronics market. With increasing usage of smartphones, laptops, smartwatches, and display devices, manufacturers are investing heavily in advanced coatings that protect screens and housings from scratches and abrasions. As consumers expect devices to maintain a “new look” for longer periods, scratch resistant coatings have become a standard feature rather than an optional enhancement.

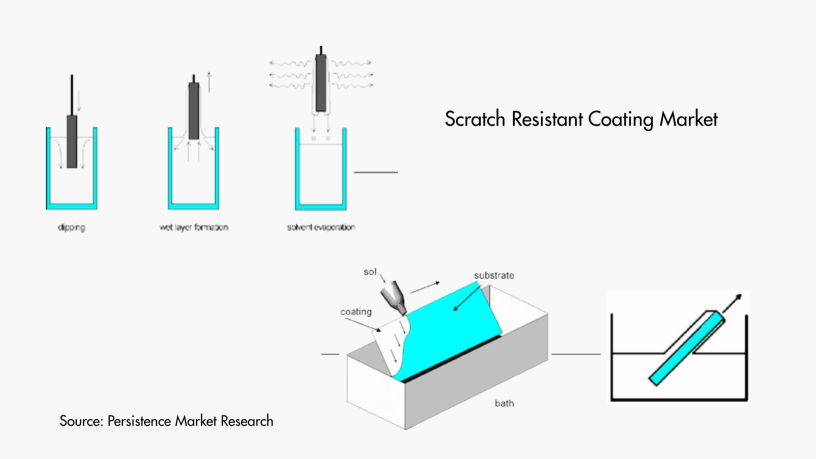

Technology Trends: Advancements in Coating Formulations

Technological innovation is shaping the evolution of the scratch resistant coating market. Traditional solvent-based coatings are increasingly being replaced by water-based and UV-cured coatings that offer improved environmental performance and faster curing times. Nanotechnology-based coatings are gaining strong traction due to their superior hardness, transparency, and resistance to micro-scratches.

Ceramic and hybrid coatings are also emerging as advanced solutions, combining scratch resistance with additional benefits such as chemical resistance, UV protection, and anti-fingerprint properties. These multifunctional coatings are particularly attractive in electronics, optics, and automotive applications, where performance requirements are becoming more complex and demanding.

Application Insights: Automotive, Electronics, and Construction

The automotive sector remains one of the largest consumers of scratch resistant coatings, accounting for a significant share of global demand. Coatings are applied to vehicle bodies, headlights, interior trims, and infotainment screens to ensure long-term protection against abrasion, dust, and daily use. As vehicle production continues to rise globally, especially in Asia Pacific, demand for these coatings is expected to remain strong.

Consumer electronics represent another high-growth application area. The increasing use of glass and plastic components in devices has amplified the need for coatings that maintain clarity while providing robust scratch protection. Meanwhile, in the construction industry, scratch resistant coatings are widely used on architectural glass, flooring systems, furniture, and wall panels, enhancing durability in high-traffic environments such as commercial buildings, airports, and shopping centers.

Regional Outlook: Market Performance Across Geographies

Regionally, Asia Pacific dominates the scratch resistant coating market due to rapid industrialization, expanding automotive production, and strong growth in electronics manufacturing. Countries such as China, Japan, South Korea, and India are major contributors, driven by large-scale manufacturing bases and increasing domestic consumption.

North America and Europe also represent significant markets, supported by advanced manufacturing technologies, strict quality standards, and strong demand for premium products. In these regions, the focus on sustainability and high-performance materials is accelerating the adoption of eco-friendly and advanced coating solutions. Emerging markets in Latin America and the Middle East & Africa are gradually gaining traction, supported by infrastructure development and rising consumer awareness.

Challenges and Constraints: Market Limitations

Despite positive growth prospects, the scratch resistant coating market faces several challenges. High raw material costs and complex manufacturing processes can increase overall production expenses, impacting pricing and profit margins. Additionally, achieving a balance between scratch resistance, transparency, and flexibility remains a technical challenge, particularly for applications involving flexible substrates.

Environmental regulations related to volatile organic compounds (VOCs) also pose constraints for traditional solvent-based coatings. Manufacturers must invest in research and development to comply with regulatory standards while maintaining performance, which can be resource-intensive for smaller players.

Competitive Landscape: Innovation and Strategic Focus

The competitive landscape of the scratch resistant coating market is characterized by continuous innovation and strategic collaborations. Key players are focusing on developing advanced formulations, expanding product portfolios, and strengthening their presence in high-growth regions. Partnerships with automotive OEMs, electronics manufacturers, and construction companies are common strategies to secure long-term demand and improve market positioning.

Investments in R&D are particularly critical, as end users increasingly seek coatings with enhanced durability, sustainability, and multifunctional properties. Companies that can offer customized solutions tailored to specific applications are likely to gain a competitive edge.

Future Outlook: Steady Growth with Expanding Applications

Looking ahead, the scratch resistant coating market is expected to witness steady growth through 2033, driven by expanding applications and ongoing technological advancements. The increasing emphasis on product longevity, visual appeal, and reduced maintenance costs will continue to support market demand. With the market projected to grow from US$ 6.4 billion in 2026 to US$ 9.3 billion by 2033 at a CAGR of 5.5%, scratch resistant coatings are set to remain a vital component in modern manufacturing and surface protection strategies.

Conclusion: A Market Built on Durability and Innovation

The scratch resistant coating market represents a critical intersection of material science, innovation, and end-user demand for durability. As industries strive to deliver high-quality, long-lasting products, the importance of advanced surface protection solutions will only increase. Supported by strong fundamentals, technological progress, and diverse applications, the market is well-positioned for sustainable growth in the years ahead.

Explore the Latest Trending Research Reports: