Introduction: Enhancing Protection in Modern Packaging

The packaging industry is undergoing a significant transformation as brands and manufacturers focus on extending shelf life, ensuring product safety, and meeting sustainability goals. Among the key innovations driving this shift are barrier coatings for packaging. These coatings play a vital role in protecting packaged goods from external factors such as moisture, oxygen, grease, aroma loss, and microbial contamination. As consumer demand for high-quality, long-lasting, and environmentally responsible packaging increases, barrier coatings have become an indispensable solution across food, beverage, pharmaceutical, and personal care sectors.

Market Overview: Size, Growth, and Future Outlook

The global barrier coatings for packaging market is showing steady and promising growth, supported by rising demand for advanced packaging materials. According to a Persistence Market Research report, the global barrier coatings for packaging market is projected to be valued at approximately US$13.8 billion in 2026. Over the forecast period, the market is expected to expand significantly, reaching around US$20.6 billion by 2033. This growth reflects a compound annual growth rate (CAGR) of 5.9% between 2026 and 2033, highlighting the increasing adoption of barrier coatings as packaging performance requirements continue to rise across industries.

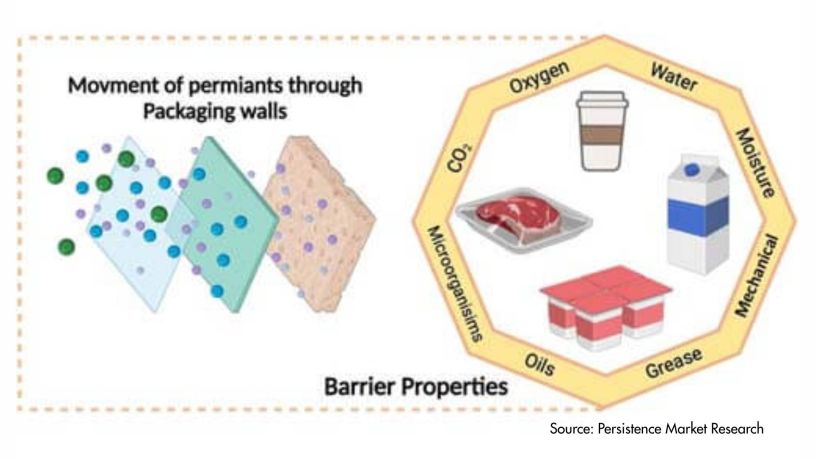

What Are Barrier Coatings for Packaging and Why Are They Important?

Barrier coatings are thin layers applied to packaging substrates such as paper, paperboard, plastics, and films to improve their resistance to gases, moisture, grease, and other environmental elements. These coatings enhance the functional properties of packaging without significantly increasing material thickness or weight. Their importance lies in their ability to preserve product quality, prevent spoilage, and reduce food waste while enabling lightweight and cost-effective packaging designs. Additionally, barrier coatings support the shift toward recyclable and biodegradable packaging by replacing traditional multi-layer plastic structures.

Get Your FREE Sample Report Instantly – Click Now

What Are Barrier Coatings Used for in Packaging?

Barrier coatings are used in packaging to protect products from external elements such as oxygen, moisture, grease, light, and odors that can degrade quality over time. They are widely applied in food and beverage packaging to extend shelf life and maintain freshness, especially for products like snacks, dairy, frozen foods, and ready-to-eat meals. In pharmaceutical and personal care packaging, barrier coatings help preserve product efficacy and safety. Increasingly, these coatings are also used to enhance sustainability by enabling paper-based and recyclable packaging alternatives to replace conventional plastic laminates, aligning with environmental regulations and consumer expectations.

Key Growth Drivers: Demand for Food Safety and Shelf-Life Extension

One of the primary drivers of the barrier coatings for packaging market is the growing emphasis on food safety and shelf-life extension. With the global rise in packaged and processed food consumption, manufacturers require packaging solutions that can maintain freshness, flavor, and nutritional value over longer periods. Barrier coatings provide effective protection against oxygen and moisture, which are major causes of food spoilage. This makes them particularly valuable in high-demand segments such as bakery products, snacks, confectionery, and frozen foods.

Sustainability Trends Fueling Market Expansion

Sustainability has emerged as a major force shaping the packaging industry, and barrier coatings are central to this transition. Traditional packaging often relies on multi-layer plastic structures that are difficult to recycle. In contrast, water-based and bio-based barrier coatings enable the use of paper and mono-material packaging formats that are easier to recycle or compost. As governments impose stricter regulations on plastic waste and consumers increasingly favor eco-friendly brands, demand for sustainable barrier coating solutions is accelerating across global markets.

Types of Barrier Coatings and Material Innovations

Barrier coatings for packaging are available in various types, including water-based, solvent-based, and bio-based formulations. Water-based coatings are gaining strong traction due to their low environmental impact, reduced volatile organic compound (VOC) emissions, and compatibility with paper-based packaging. Bio-based coatings, derived from renewable resources such as starch, cellulose, and proteins, are also emerging as innovative solutions that align with circular economy principles. Continuous advancements in material science are improving the performance of these coatings, enabling them to compete with conventional plastic barriers.

End-Use Industries Driving Demand

The food and beverage industry remains the largest end user of barrier coatings for packaging, accounting for a significant share of global demand. The pharmaceutical industry also represents a key segment, where barrier properties are critical for protecting medicines from moisture and oxygen exposure. Additionally, personal care and household product packaging increasingly utilize barrier coatings to enhance durability and product integrity. The growth of e-commerce has further boosted demand, as packaging must withstand longer transportation times and varying environmental conditions.

Regional Insights: Leading and Emerging Markets

North America and Europe dominate the barrier coatings for packaging market due to strong regulatory frameworks, advanced packaging technologies, and high consumer awareness regarding sustainability. These regions have seen rapid adoption of recyclable and paper-based packaging solutions, driving demand for high-performance barrier coatings. Meanwhile, Asia Pacific is emerging as a high-growth region, supported by expanding food processing industries, rising urbanization, and increasing consumption of packaged goods in countries such as China and India. Latin America and the Middle East & Africa are also gradually adopting barrier coating technologies as packaging standards evolve.

Challenges and Market Constraints

Despite favorable growth prospects, the barrier coatings for packaging market faces certain challenges. Performance limitations compared to conventional plastic laminates, especially in high-moisture or high-fat applications, can restrict adoption in some use cases. Additionally, cost considerations associated with advanced or bio-based coatings may deter small and medium-sized manufacturers. However, ongoing research and development efforts are steadily addressing these challenges by improving coating efficiency, scalability, and cost-effectiveness.

Future Outlook: Innovation and Strategic Opportunities

The future of the barrier coatings for packaging market looks promising, driven by innovation, sustainability goals, and evolving consumer preferences. Manufacturers are investing in next-generation coatings that combine high barrier performance with recyclability and compostability. Strategic collaborations between coating producers, packaging converters, and brand owners are expected to accelerate commercialization and adoption. With the market projected to grow from US$13.8 billion in 2026 to US$20.6 billion by 2033 at a CAGR of 5.9%, barrier coatings will continue to play a critical role in shaping the future of efficient, sustainable, and high-performance packaging solutions.

Explore the Latest Trending Research Reports: